Last month saw the 5G Factory of the Future project draw to a close, hosted at AMRC North West, MTT attended the closing event alongside other partners the University of Sheffield, BAE Systems, Digital Catapult, IBM and AQL.

Attended by over 75 representatives from businesses, leading manufacturers and academics, the event concluded the £10m+ 5G Factory of the Future project which originally launched in December 2020. Aiming to further develop understanding and implementation of 5G technologies within manufacturing, the project has seen delivery of the UK’s first fully operational 5G Standalone (5G SA) testbed.

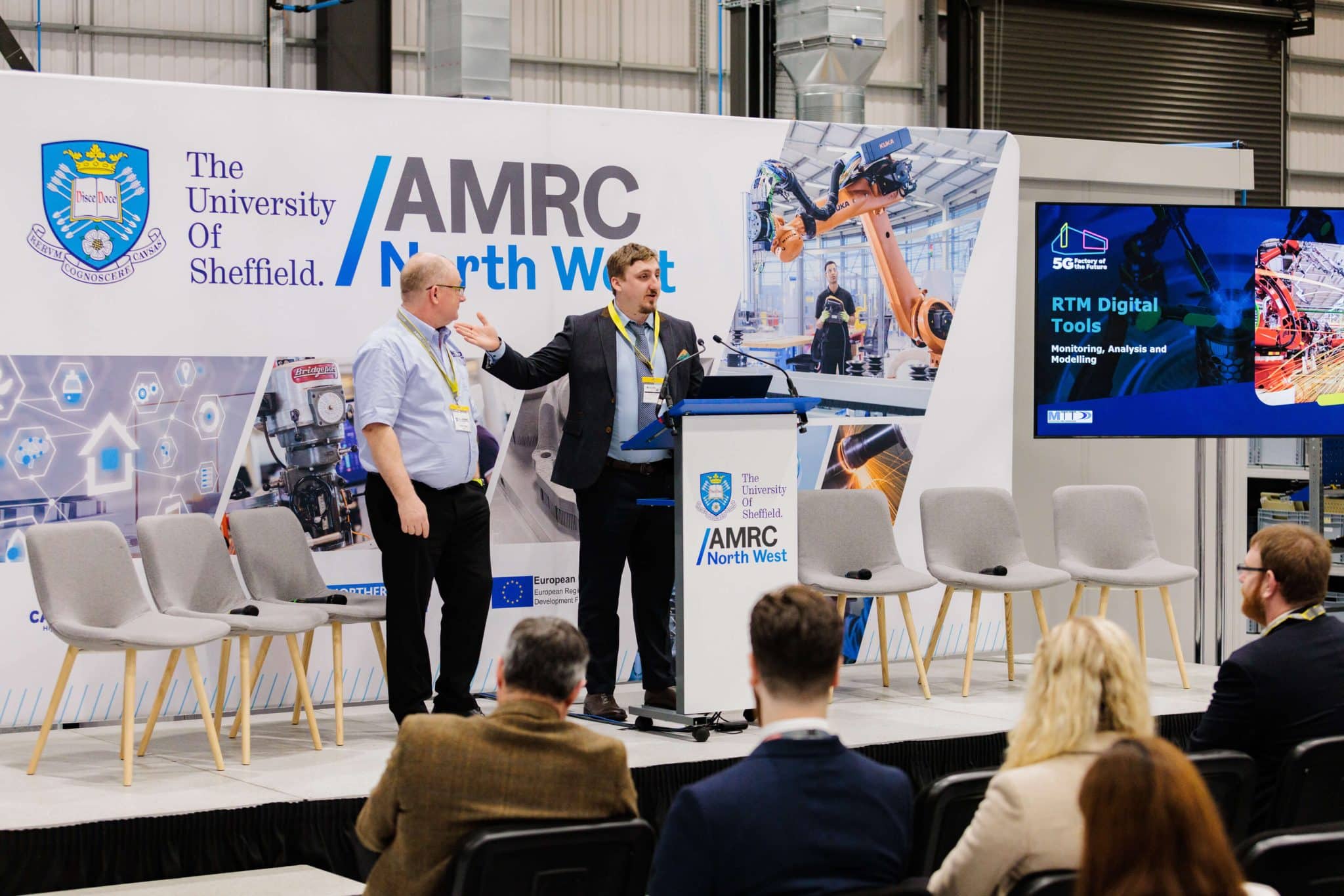

The final event saw all project partners come together to discuss findings, continued research, and the main outcomes from the project, which was part-funded by the Department for Science, Innovation and Technology (DSIT). Throughout the day there were talks from the main partners, including AMRC’s Commercial Director and an open panel discussion around the future of 5G and the potential for manufacturing in the future using this technology.

Steve Taylor, Software Engineer and Charlie Allen, Integration Engineer, presented MTT’s own findings from the project, discussing real time machine monitoring over 5G, with adaptive control, utilising MTT’s 5G ready Sensor tool kit. The presentation also contained demonstrations of MTT’s Digital Twin software, displaying animations of its capabilities.

During the presentation, Charlie Allen explained: “Taking part in the 5G Factory of the Future project has meant we have accelerated the development of our digital technologies, confirming that the future is digital. Our work at MTT, although continuing to remain within machine tool maintenance and support, is expanding further into the digital market.”

Dr Aparajithan Sivanathan, project lead for the 5G Factory of the Future programme and head of digital technology at AMRC North West said: “The 5G FoF project has successfully delivered the largest manufacturing testbed in the UK, with 5G standalone capability, proven working 5G use cases and developed native 5G devices.

We have also created a business model that will sustain the testbed beyond the end of the project. 5G is going to be the future and we’re now thinking about the next phase.”

The project drew many conclusions about the future of manufacturing, including the drive for sustainability and the possibilities that 5G provides for sustainable manufacturing. Overall, partners have utilised this project to further develop understanding of 5G and what the future of manufacturing looks like in a range of environments.

Speaking about MTT’s role within the 5G project and the impact of this on their future work, MTT’s Chief Technology Officer Dr Patrick Land said: “The 5G FoF project has enabled MTT to enhance our digital products, with 5G delivering a faster and more connected platform for MTT machine monitoring and control. MTT is driving the integration of machine monitoring systems with 5G offering enhanced connectivity and improving our digital twin capabilities.”

More information about the 5G Factory of the Future project can be found via AMRC’s website, or if you wish to speak with MTT’s engineers about our software capabilities or machine tool maintenance services, do not hesitate to contact our team.